annual cutting

Have any questions?

+44 1234 567 890

Lorem ipsum dolor sit amet:

24h / 365days

We offer support for our customers

Mon - Fri 8:00am - 5:00pm (GMT +1)

Cybersteel Inc.

376-293 City Road, Suite 600

San Francisco, CA 94102

Have any questions?

+44 1234 567 890

Drop us a line

info@yourdomain.com

Lorem ipsum dolor sit amet, consectetuer adipiscing elit.

Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec.

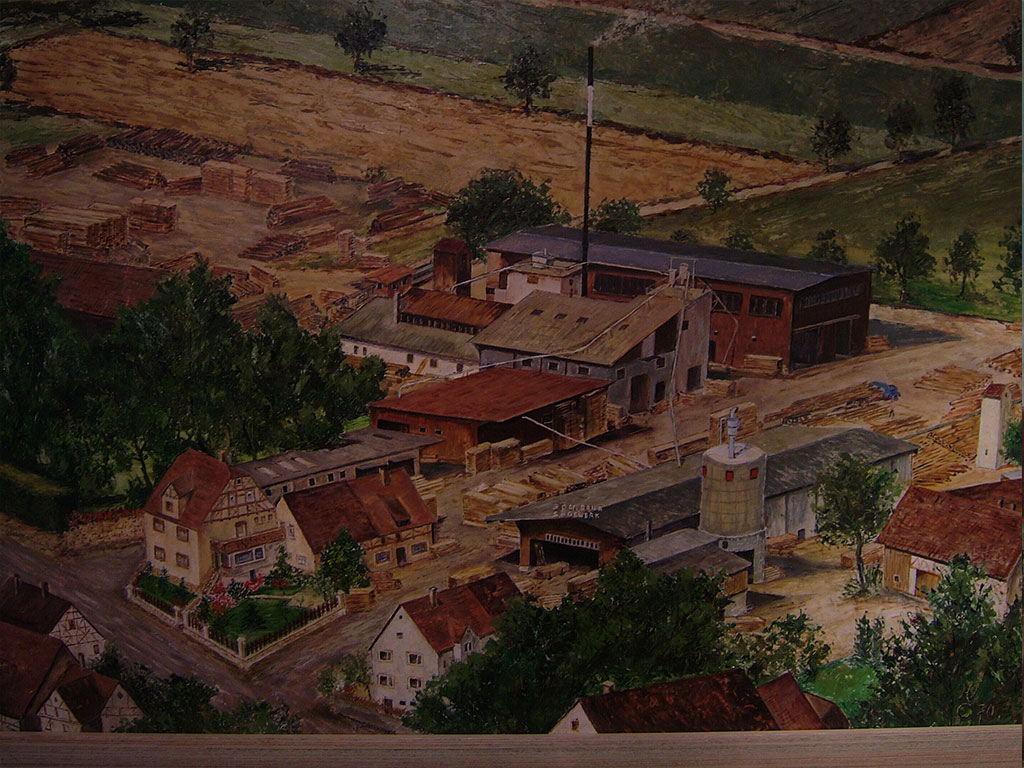

We are a "family" at Holzwerk Baur! On the one hand, we mean it literally as we are now the fifth generation operating Holzwerk Baur, on the other hand a family-like, respectful, and trusting atmosphere in the whole business is important to us. We demand the highest quality of not just our products. Short decision-making processes make it possible for our competent team to achieve the best-possible and most efficient results in close collaboration with you.

After the trunks arrive in our sawmill, they bark is first removed, are then measured, trimmed, and sorted by wood type and quality. At the same time, the sorting forms the basis to optimise the sawn timber yield.

The sorted log sections are stored here until the wood is processed according to your specific wishes.

We have created a production cycle at Holzwerk Baur in which every log is used optimally and virtually without any waste. The profiler line with an 80 m/min cycle processes the logs into a clean square cut, which is then sawn by up to ten saw blades into planks, frames, and floorboards.

Recycling is a trending topic in our industry. The production process results in wood off-cuts. These are all reused sustainably. Wood chips in the paper factory, sawdust for chipboard production, wood shavings for the packaging industry, and bark for gardens and landscaping or your own heating.

annual cutting

daily cutting

log storage

Solid construction timber plant expands for Listen-KVH® (solid construction timber) up to 14 m long and 320 mm wide

Storage capacity for finished goods expands with a light construction shop

Planed goods product portfolio is extended when Peter Sailer joins us as Sales Manager

Frederik Baur joins the company (fifth generation)

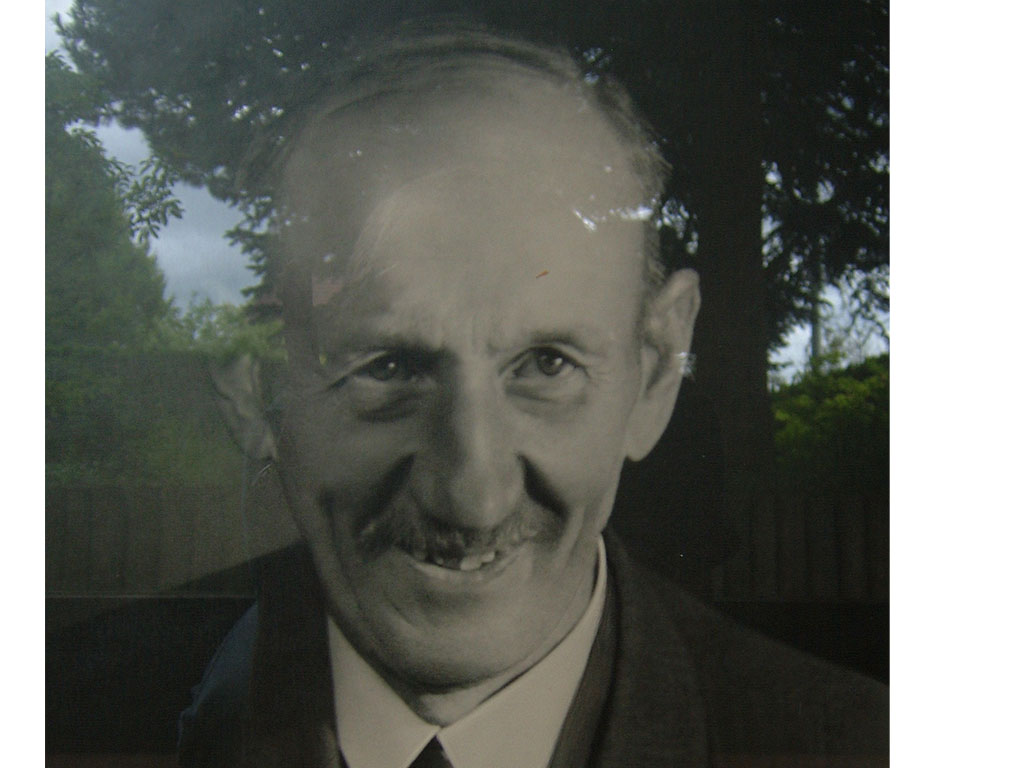

The company grows under the leadership of the brothers Hermann and Hans Baur, who now completely take over the Holzwerk. The plant is continuously expanded – the last manufacturing hall is first completed in 2004.

A part of the plant is destroyed again in a fire.

Hermann Baur Senior expands the company into a fully mechanised operation with 35,000 solid cubic metres of logs annually. The brothers Hermann Baur Junior and Hans Baur join the company in the same year as Directors, each holding one-third of the company shares.

Hermann Baur joins the company, heralding in the next series of developments: bigger workshops and a steam engine to generate power.

Wood impregnation is started after reconstruction.

The plant is completely destroyed in a fire.

The first frame saw is set up.

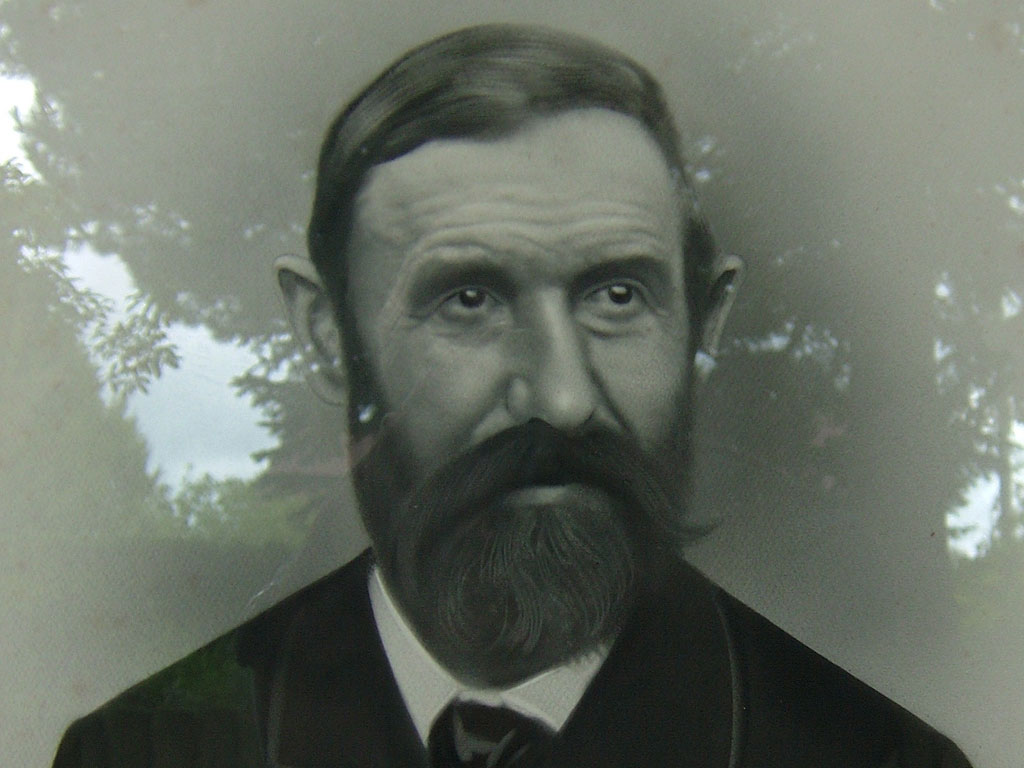

Under Johannes Baur, the carpenter’s work shop develops into a sawmill.

artholomäus Baur’s carpenter’s workshop